CREATING TEMPLATES

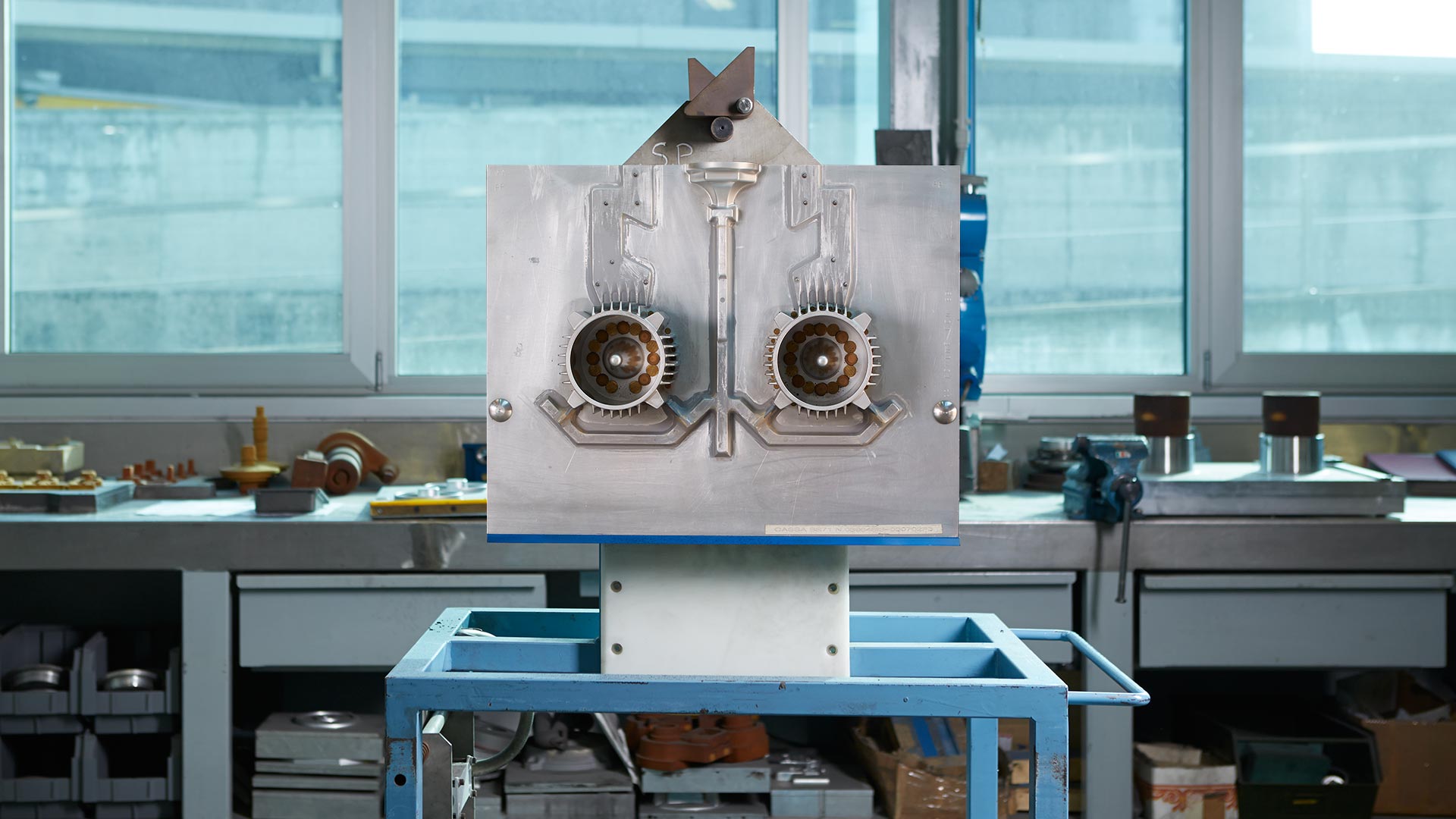

Templating has been structured using traditional and numerical control machines to build templates, using a CAD/CAM CATIA’ workstation to process the design provided by the client; to study and optimise the best efficiencies of the product itself. The department is managed by highly skilled personnel with considerable experience.

This is an important aspect. Most foundries use an external supplier for their feasibility studies. Here in GDC Cast the study is done internally. After the client has sent the 3D we try to get greatest capacity efficiency possible.