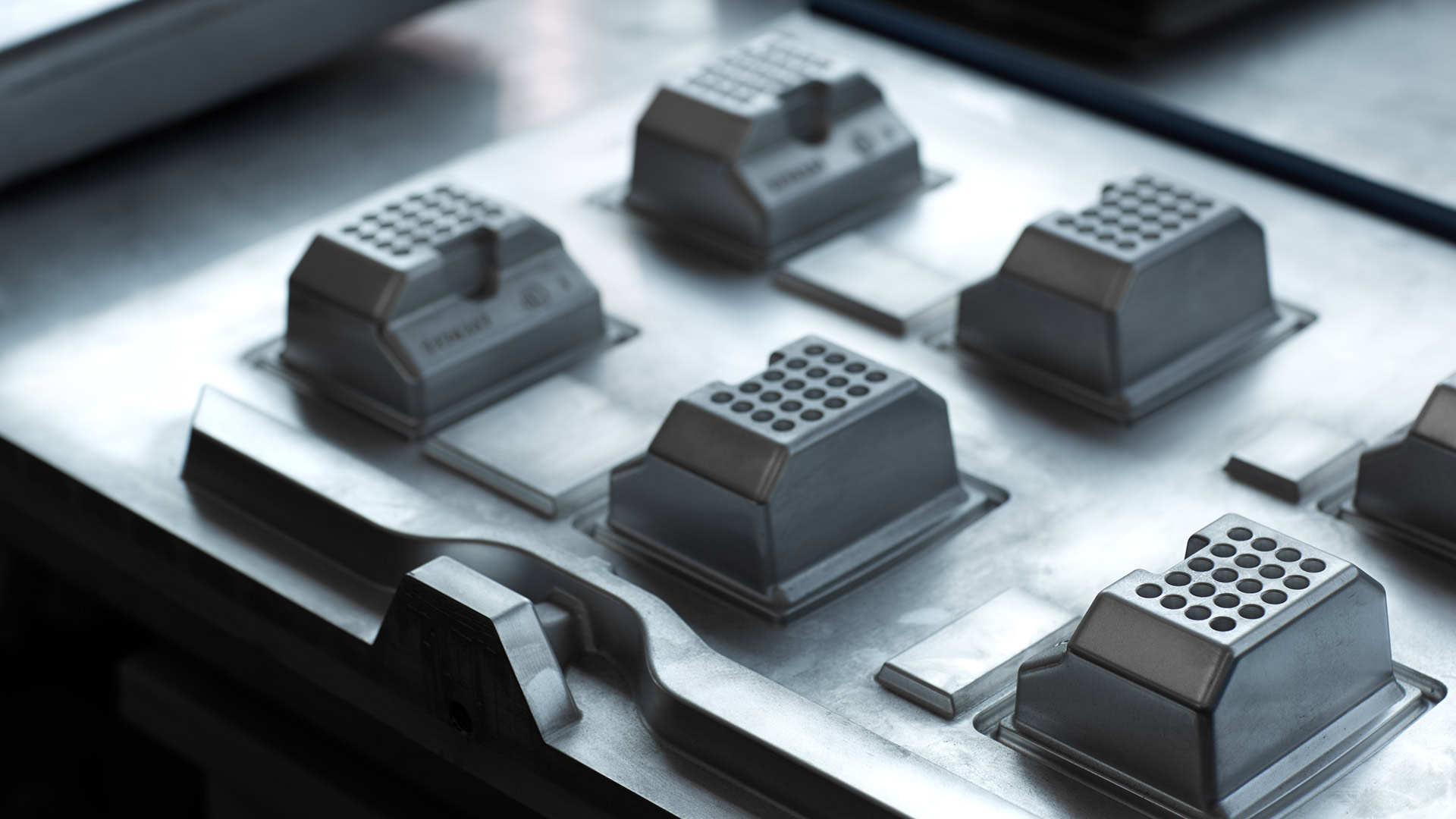

A RELIABLE PARTNER TO COLLABORATE WITH FOR CUSTOM-MADE PRODUCTIONS

TAILORING

Working with a foundry does not mean finding a supplier; it means finding a company to collaborate with.

Each client is a partner to share the design stage with and to whom we offer ongoing advice.

Our clients know they will always be given a solution even when it seems impossible: what counts is the cast-iron. Moreover, the top level GDC Cast technology guarantees higher quality standards and the possibility for greater smelting than traditional foundries. So we can give each client a tailored offer, made-to-measure.

The presence of two, 4-ton induction furnaces enables us to diversify cast iron type flexibly and increase cycles.

Traditional foundries work the cupola furnaces which determine the recipe as melting progresses. To achieve the cast-iron type required by the client they need to work a lot more than an induction one with a specific receipt decided on 4 tons. That recipe can vary from load to load, or can be “long campaign”, that is unique for the entire working day; but we are very flexible over diversifying daily with several recipes.

That is why we are also much faster and more accurate. We are sure that once we have found the right recipe, it will suffer no change till melting is over.